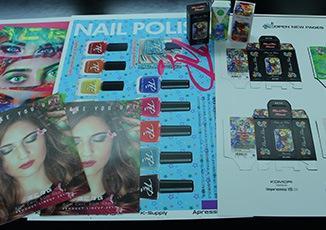

Products

You can view Komori product information.

Discovering print production issues and streamlining print production

Quality and reliability in an eco-friendly and economical innovative UV curing system

CMS based on offset printing that only a press maker can provide

Integrated Print Quality Control Systems to Improve Productivity for Printing Companies

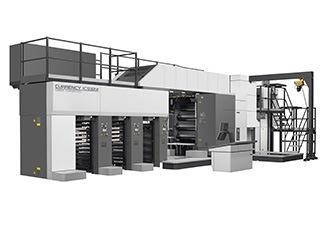

Komori currency printing press symbolizing ulitmate technological mastery

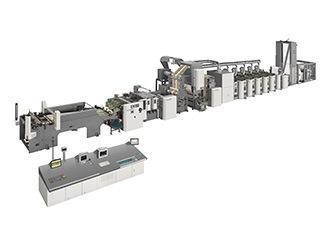

Folder with high folding precision due to high operating speed and robust construction

Cutter and Cutting systems bring sophisticated automation and labor savings