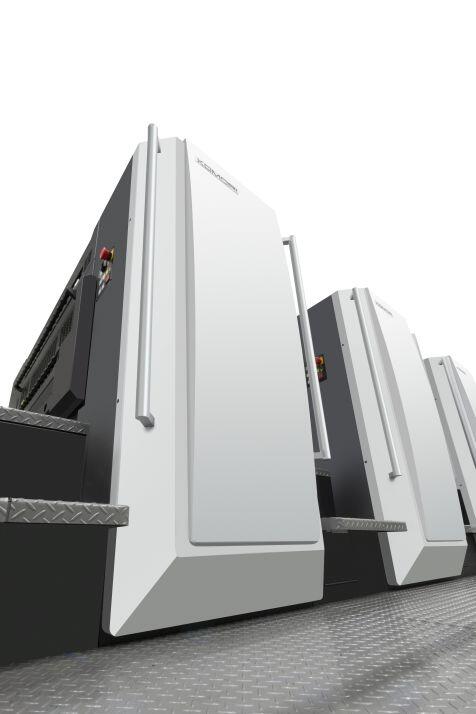

LITHRONE GX40 advance

Product image for illustration purposes only. Actual product may vary.

Concept

Lithrone GX40 advance:

Achieving improved productivity and digital transformation for package printing flagship model

Boasting a world-class return on investment*1, the Lithrone GX/G advance series is being introduced globally.

To achieve further productivity growth and sustainable management, Komori has developed the Lithrone GX/G advance Series equipped with revolutionary new functions.

By means of three eco-conscious functions*2, the press reduces power consumption by up to 18%*3 while printing and realizes stable feeder and delivery operation to cut wastepaper usage, thus both achieving reduced greenhouse gas emissions and high productivity.

Leveraging the latest printing technology, this latest development from Komori reduces energy costs and enhances operator eciency, propelling businesses to a new heights.

The Komori Lithrone GX40 advance series takes productivity to the highest level with added specifications and features to include the needs of the packaging market, most notable is the capability to run larger sheet size up to 750 × 1,050, sheet thicknesses up to 1mm and stable, high-quality printing up to 18,000 sheets per hour. In particular, "Super Short Makeready," devised to reduce changeover time, including special color, minimizes job changeover times.

*1 ROI (Return on Investment)

*2 Smart Inking Flow, DC blower and e-Mist

*3 Effect of Smart Inking Flow and DC blower together

Features

- "Super short makeready*1" minimizes job changeover time, including special colors.

Capable of meeting various requirements in packaging printing, from short runs to large batches. - A wide variety of configurations to suit your needs and achieve unparalleled productivity*2

- ①Feeder delivery, ②Dampening system Komorimatic, and ③Operating systems were enhanced.

Promotes high-speed production, along with reduced makeready time, and reduced waste, providing a world-class ROI. - Using KP-Connect Pro to link prepress, press and postpress, optimizes the overall production process, helping to create smart factories that maximize productivity.

- Enhanced KID screen layout helps operators move through press functions faster, improving overall work efficiency.

- An eco-friendly offset printing press with three environmentally responsible press functions*3 that reduce power consumption, paper waste, and greenhouse gas emissions.

*1 Makeready solutions that combine multiple functions to help reduce makeready time, even in short run package printing.

*2 Optional combinations are possible, such as 900 mm plinth, Automatic Non-stop feeder and delivery combined with logistics to enable non-stop production, multiple delivery piles and extended delivery specifications for the drying section.

*3 Smart Inking Flow, DC Blower, e-Mist

| Model | LITHRONE GX40 advance | |

|---|---|---|

| Number of colors | 5-8 | |

| Max. sheet size | mm | 750×1,050 |

| Max. printing area | mm | 740×1,040 |

| Plate size | mm | 811×1,055 |

| Feeder pile height | mm | 1,550(plinth: 450) |

| Delivery pile height | mm | 1,550(plinth: 450) |

* Maximum printing varies according to printing conditions.

* Performance and numbers may differ from specifications herein. Specifications my also be modified for product improvements.