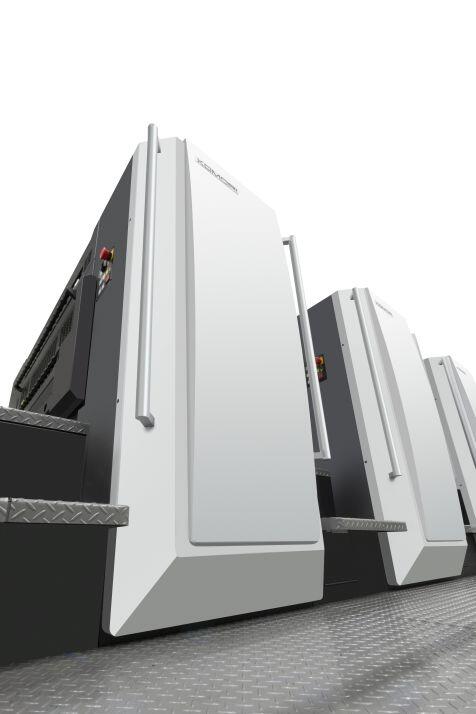

LITHRONE GX40RP advance

Product image for illustration purposes only. Actual product may vary.

Concept

Lithrone GX40RP advance:

The worlds most advanced dedicated, two-sided, printing press, delivering unparalleled productivity on a wide range of stocks for commercial printing or package printing

Boasting a world-class return on investment*1, the Lithrone GX/G advance series is being introduced globally.

To achieve further productivity growth and sustainable management, Komori has developed the Lithrone GX/G advance Series equipped with revolutionary new functions.

By means of three eco-conscious functions*2, the press reduces power consumption by up to 18%*3 while printing and realizes stable feeder and delivery operation to cut wastepaper usage, thus both achieving reduced greenhouse gas emissions and high productivity.

Leveraging the latest printing technology, this latest development from Komori reduces energy costs and enhances operator eciency, propelling businesses to a new heights.

The Lithrone GX40RP advance combines Komori technology and expertise, utilizing a transfer mechanism that offers a powerful advantage when requiring stable, high-output double-sided printing. The simple, non-reversing sheet transport can flexibly adapt to a wide array of stocks from thin paper, to heavy board packaging, while maintaining high front-to-back register accuracy for the highest quality, double-sided printing. It furthermore minimizes paper costs and uniquely shares plates with its single-sided press counterpart for a more efficient production process.

*1 ROI (Return on Investment)

*2 Smart Inking Flow, DC blower and e-Mist

*3 Effect of Smart Inking Flow and DC blower together

Features

- The RP press technology provides two-sided printing without flipping the sheet for the highest register and print quality.

- Since the press does not flip the sheet, there is no need for gripper margins at the tail, reducing paper waste compared to traditional perfecting presses.

- ①Feeder and delivery, ②Komorimatic dampening system, and ③Operating systems were enhanced.

Promotes high-speed production, along with reduced makeready time, and reduced waste, providing a world-class ROI*1. - Using KP-Connect Pro to link prepress, press and postpress, optimizes the overall production process, helping to create smart factories that maximize productivity.

- Enhanced KID screen layout helps operators move through press functions faster, improving overall work efficiency.

- An eco-friendly offset printing press with three environmentally responsible press functions*2 that reduce power consumption, paper waste, and greenhouse gas emissions.

*1 ROI (Return on Investment)

*2 Smart Inking Flow, DC blower and e-Mist

| Model | LITHRONE GX40RP advance | |

|---|---|---|

| Number of colors | 4-10 | |

| Max. sheet size | mm |

750 × 1,050 |

| Max. printing area | mm |

740 × 1,040 [ 710 × 1,020 special specification ] |

| Plate size | mm |

811 × 1,055 [ 800 × 1,030 special specification ] |

| Feeder pile height | mm |

1,850 |

| Delivery pile height | mm |

1,400 |

* The above specs require either H-UV, H-UV L (LED) or UV.

* Maximum printing speed may differ depending on chosen specifications and printing conditions.

* Performance and numbers may differ from specifications herein. Specifications may also be modified for product improvements.