MBO T50

Concept

Folder with high folding precision due to high operating speed and robust construction

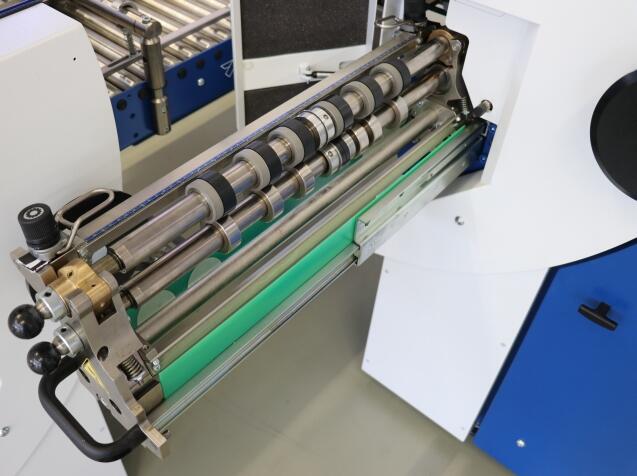

The MBO T50 is MBO’s answer to wide-ranging customer requirements in the 50 x 70 cm half-size format. Equipped with the latest generation M1 machine control, it can be optimally configured for every application. The T50 offers more than simply the tried and trusted MBO standards such as the belt drive and the slitter shafts with plug bearings. Many of the high-end features of its “big brothers” are also available as options. With a Vivas vacuum system, slitter shaft cassette and comprehensive automation options, it can be optimally tailored to any job requirements. It features a valuable equipment level as standard, including an intuitive operation touchscreen and marking-free sheet alignment via high-speed guides in the second folding unit.

Features

Machine control M1 Basic with touchscreen(Standard feature)

The first folding unit of the MBO T50 with machine control M1 Basic is equipped with a touchscreen. The screen diagonal is 10.1“. In addition, the first folding unit is equipped with sheet monitoring by means of optical sensors. Basic functions such as “Start,” “Stop” and “Production” can be carried out at the subsequent folding units with machine control M1 Basic. The speed of the folding units is set manually.

A router for the RAS Remote Access Software is optionally available. This is a prerequisite for the optional Datamanager 4.0. In connection with the machine control M1 Basic, the Datamanager 4.0 has limited functions.

Machine control M1 Advanced with touchscreen(Alternative feature)

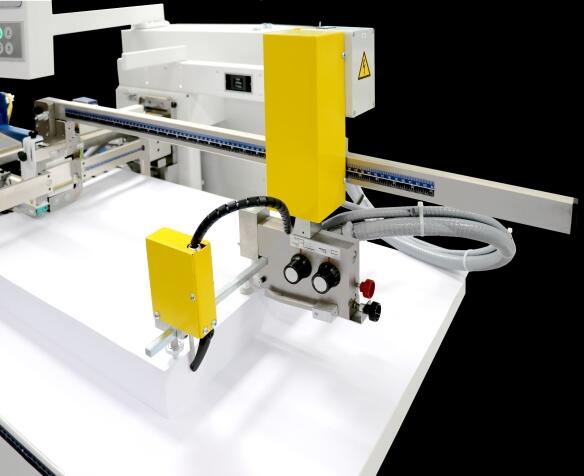

The machine control M1 Advanced can be operated from any folding unit. The screen diagonal of the adjustable touchscreen on folding unit I is 15.6” and on folding unit II 10.1”.

The operator is optimally supported when setting up a new job. Common standard folding impositions are preconfigured in “Quick Mode”. Every technically possible and sensible variant can be put together in “Expert Mode”. In addition, optimal sheet gaps and speeds are automatically calculated and set in all folding units. In addition, the machine control M1 Advanced features sheet monitoring across all folding units. This includes sheet length control and sheet-monitoring using sensors.

The control includes a router for RAS Remote Access Software. The machine control M1 Advanced is also compatible with the Datamanager 4.0, a software package for production planning and analysis. Among other things, Datamanager 4.0 contains a folding imposition catalogue which supports the user during set-up.

| model |

MBO T50 |

|

|---|---|---|

| Max. sheet size | mm |

Pile feeder:530x840 |

| Min. sheet size | mm | Pile feeder :150x150 Continuous feeder:150x180 |

| Sheet thickness (weight) | gms | 35~250 |

| Speed | m/min | 230 |

|

Number of buckles |

plates | 4 or 6 |

| Available configurations | Second unit for parallel folding(4 or 6 plates) |

* Performance and numbers may differ from specifications herein, and specifications may also be modified for product improvements.